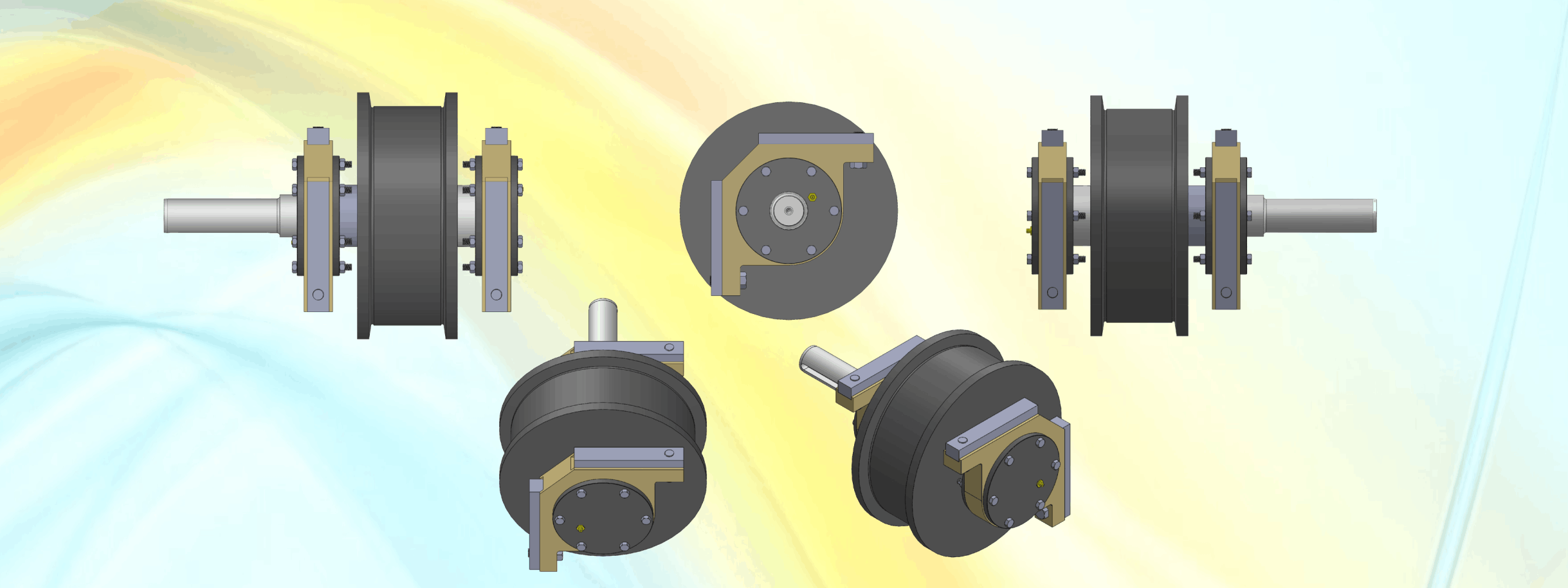

WHEEL ASSEMBLIES

WHEEL ASSEMBLIES

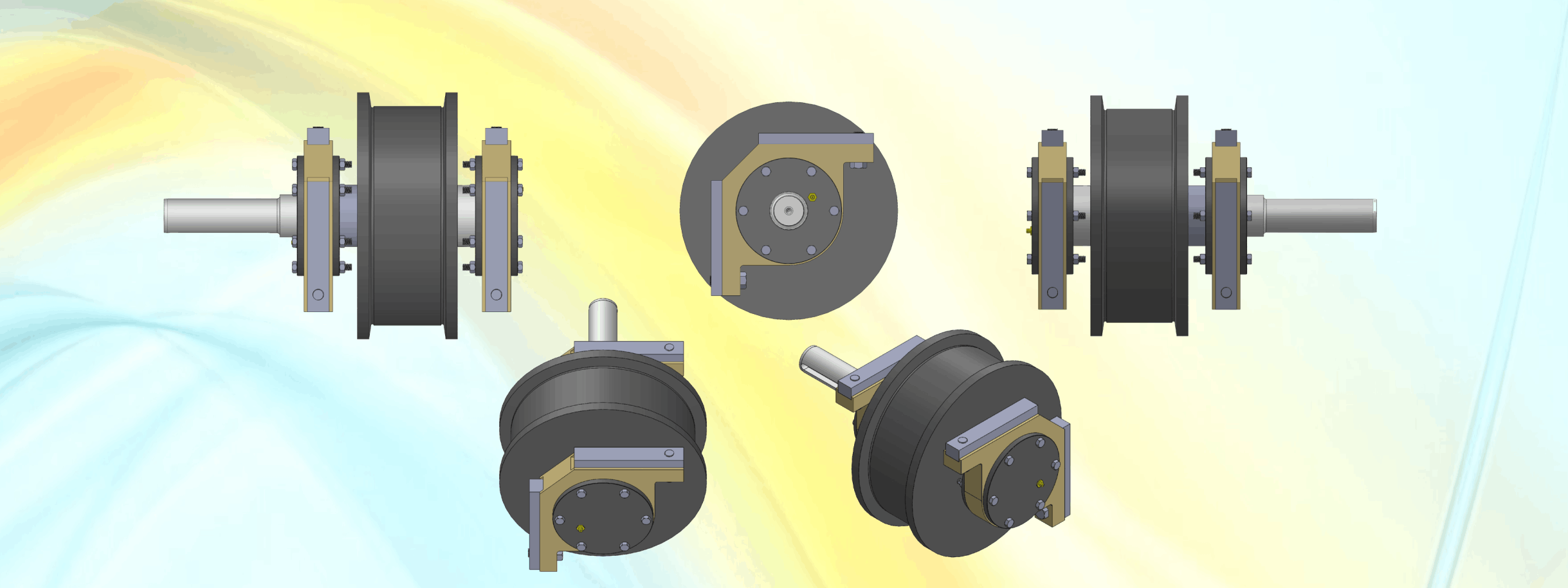

Wheel assemblies play a critical role in the operation of equipment such as EOT (Electric Overhead Travel) cranes, trolleys, funicular trains, and other similar systems where reliable movement and load-bearing capability are essential. These wheels are typically manufactured from high-strength forged blanks, carefully selected and processed to meet specific performance and durability requirements. Commonly used materials include EN9 and EN24 grades, known for their excellent mechanical properties and wear resistance.

After the initial machining process, the wheels undergo volume hardening—a heat treatment process that enhances the core and surface hardness, ensuring they can withstand heavy operational stresses and resist wear over prolonged use. This treatment is critical in extending the service life of the wheels under continuous and demanding load conditions.

The wheel shafts are manufactured from low-carbon steel and undergo appropriate heat treatment to achieve the desired mechanical properties such as strength and toughness. They are then precisely machined to exact tolerances, particularly at the bearing seat and wheel mounting areas, to ensure a secure, durable, and dimensionally accurate fit within the assembly.

Each wheel assembly is equipped with anti-friction roller bearings, which are selected based on the required dynamic load-carrying capacity. These bearings reduce rolling resistance, facilitate smooth operation, and enhance the overall efficiency and lifespan of the assembly.