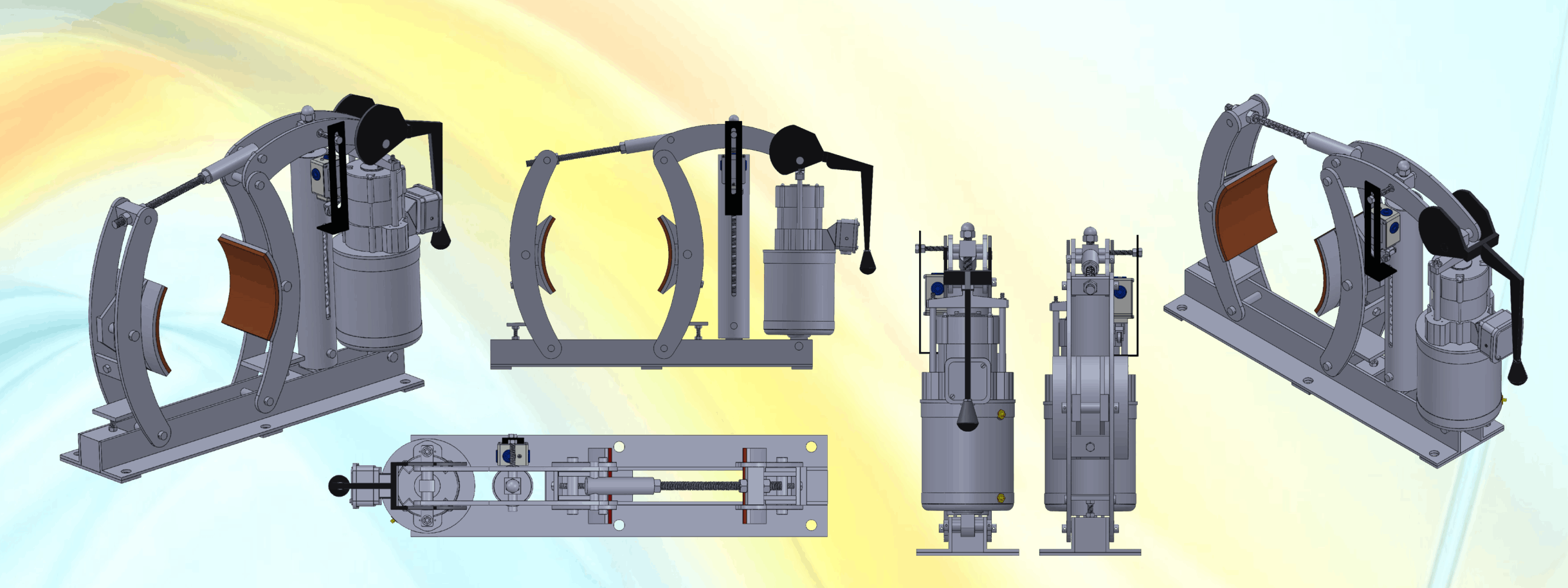

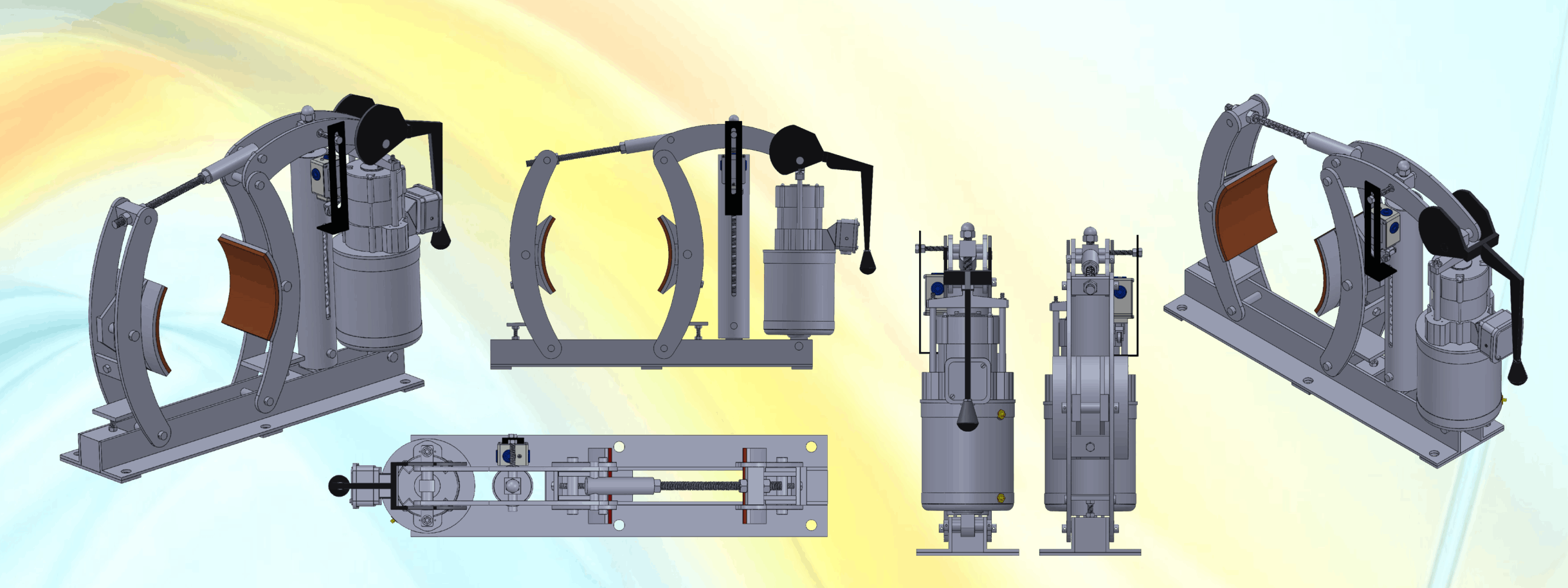

THRUSTER BRAKES - ST

THRUSTER BRAKES - ST

Thruster brakes are fail-safe brakes that are spring applied and use an electro-hydraulic thruster to hold the brake open. When supplied power, the thruster piston rod extends and the brake is released. If the thruster is turned off or power is lost, the piston rod retracts automatically and the spring locks the brake.

Steel Plants, Material Handling Cranes, Foundries, Forging Plants and Conveyors.

Meetech Industries Brakes models MBT are designed with a robust construction and simplicity in mind, featuring a minimal number of parts. This streamlined design helps to reduce maintenance problems and significantly minimize downtime, ensuring reliable and efficient operation over time.

The design of Meetech Industries brakes ensures the efficient transmission of braking force, with the braking action being evenly distributed over both shoes. This provides maximum stopping power while minimizing the wear of the shoe linings. Additionally, the large bearing area and close tolerances contribute to ensuring minimal wear on the supporting pins, enhancing the durability and performance of the braking system.

The shoe linings of Meetech Industries brakes are made from asbestos-based woven material, which is known for its high coefficient of friction and low wear rate. This material ensures reliable performance over time, as it offers excellent frictional properties while maintaining durability. The linings are typically riveted to the shoe, providing secure attachment and long-lasting effectiveness in braking performance.

The shoe adjustment feature allows for the uniform receding of both shoes, which can be easily adjusted by turning a single shoe adjustor bolt located on the lever arm. This simple adjustment mechanism ensures that both shoes move evenly, contributing to consistent braking performance. Additionally, the adjustment can be securely locked in place using a check nut, ensuring that the settings remain stable and unaffected by vibrations or external forces.

The brakes are designed with shoe positioners placed under the brake shoes to securely hold them in position, ensuring they remain rigidly fixed. This feature prevents the shoes from tilting or riding on the drum when the brakes are released, maintaining the integrity and smooth operation of the braking system. By securing the shoes in place, the positioners contribute to the overall reliability and performance of the brakes, ensuring consistent and effective braking action.

The braking torque can be easily set and maintained with convenience, allowing for precise adjustments to meet specific requirements. Once the desired torque setting is achieved, each position can be securely locked in place to prevent any disturbances caused by vibration or external factors. This feature ensures that the braking torque remains consistent, providing reliable and effective braking performance over time.

Meetech Industries Thruster brake models MBT are designed with an electrically released and spring-loaded mechanism. The release of the brake shoes is triggered by energizing the three-phase thruster, which counteracts the spring force, causing the shoes to move away from the drum through a lever/arm linkage system. When the three-phase thruster is de-energized, the shoes are pushed back against the drum, effectively engaging the brake. This design ensures that the brake remains fail-safe during power outages.